Tips and Tricks

Here you will find a series of instructions and suggested solutions that can be helpful when processing weldable materials.

Joining three parts

...to be continued

Joining three parts

A special feature of processing fabric coated on one side with TPU is the fact that only the TPU sides of the individual parts can be welded together.

You could also only use material coated on both sides. However, its surface cannot be touched with an iron without leaving processing marks.

Even if baking paper is placed underneath, unsightly fusion marks remain.

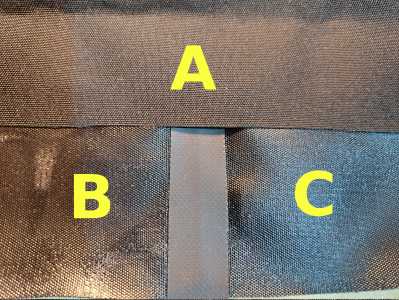

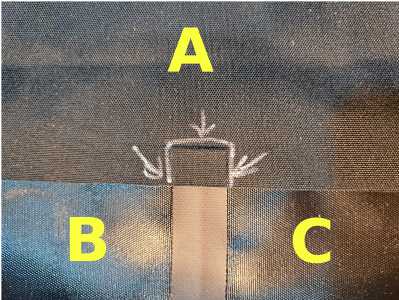

So at some point you are faced with a situation like the one in the picture.

It doesn't necessarily have to be three parts, part B and part C can also be the two ends of a circumferential strip or a tube, for example,

So how do you make a watertight connection in such a constellation?

The easiest way is to use a strip of material coated on both sides with TPU.

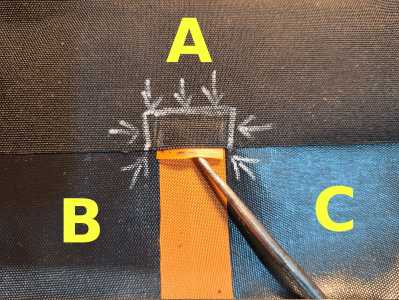

First connect parts B and C with it.

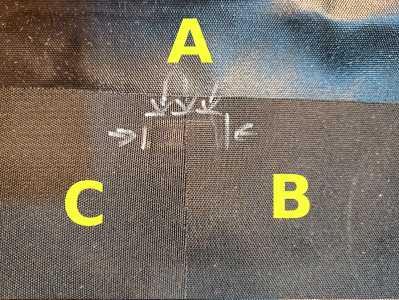

Leave the iron on a little longer in the marked areas.

The TPU must fuse well and completely together, especially in these areas, in order to create a watertight and stable connection.

Also pay extra attention to the marked area on the other side.

Use the awl to test whether everything is completely bonded together.

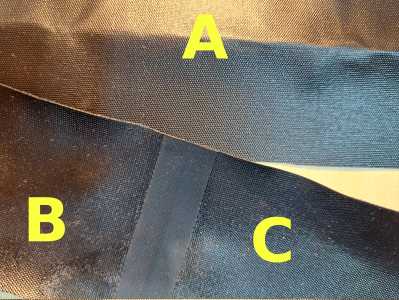

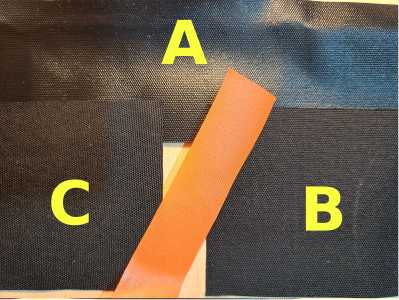

If you don't have a material coated on both sides with TPU, use a strip of the same material as the individual parts.

For better visualisation, I have chosen an orange strip here.

We use the strip to join part B and part C.

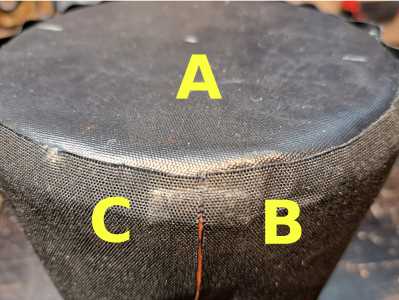

The strip is not welded up to the edge of the fabric but only up to half the seam width with part A.

In the illustration, this is the area between the fabric edge of part B and C and the marking on the strip.

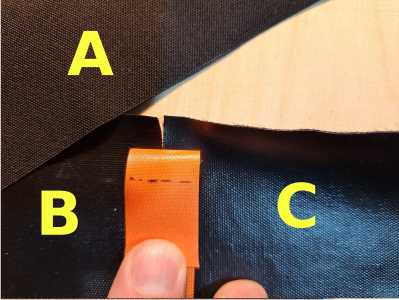

As you can see, the strip is folded over. Part A is then placed on top and welded.

Pay particular care and attention to the marked areas.

The protruding end of the strip can now be cut off.

A small pocket remains, which can be filled with SeamGrip for safety and stabilisation.

...to be continued

diy@einbeispiel.de